Im Folgenden finden Sie einige typische Referenzen von Geräten, die wir hergestellt haben.

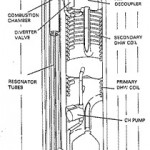

Cargill Bio-Chemical CO, LTD China

R.T.O for thermal oxidation of process gas with hydrocarbon based vapors

Combustor, used to completely burn hydrocarbons entrained in a nitrogen stream.

including a heat recovery system to preheating process air.

Explosion proof construction.

Placed within a Atex restricted zone.

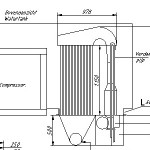

Lapicor NV

R.T.O for thermal oxidation of process air with hydrocarbons and methylene chloride

Layout: Combustor for the treatment of proces air poluted with hydrocarbons and methylene chloride

Heat of the R.T.O will be recuperated by a hot water boiler.

Complete boiler of stainless steel, one track flame tube boiler.

Cargill

R.T.O for thermal oxidation of process gas with hydrocarbon based vapors, type Combustor.

1 MW Combustor, used to completely burn (<1 mg/nm3) hydrocarbons entrained within a nitrogen stream.

Starts up and shuts down several times a day (full capacity reached in 10 Min).

Explosion proof construction.

Placed within an Atex restricted zone.

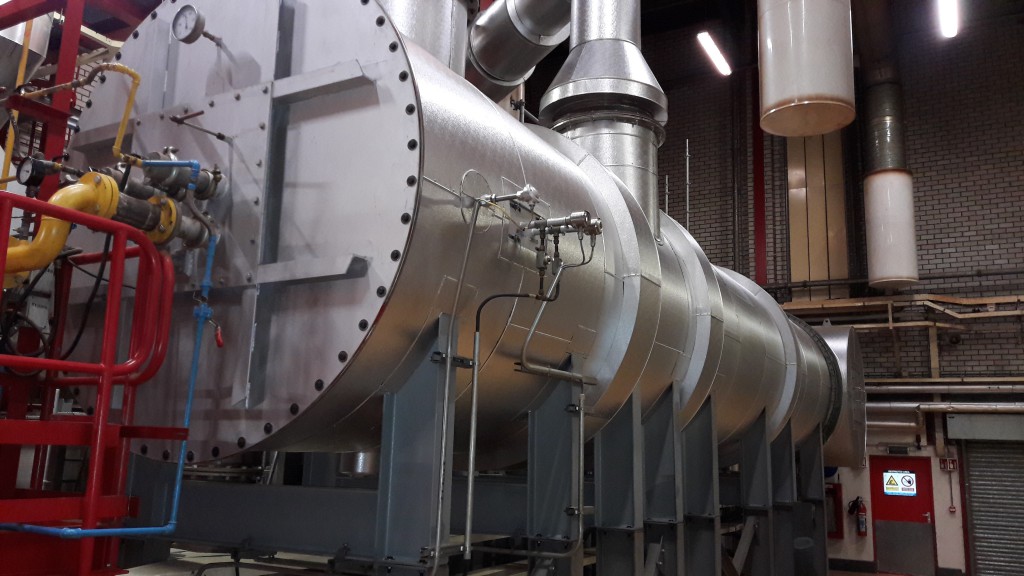

Fujifilm

R.T.O for thermal oxidation of process air with vapors.

Combustor for the treatment of 30.000 Nm3/hr polluted with solvents.

The heat of a gas turbine is used to preheat the polluted air.

Then the air is further pre-heated with the help of the exhaust gasses and disposed off through a steam boiler and hot water unit.

Steam boiler is a one track flame tube boiler with integrated economiser (10 tons/hr @ 32 Bars).

![20140910_133855 (2) (800x424)[1] 20140910_133855 (2) (800x424)[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/20140910_133855-2-800x4241-150x150.jpg)

![IMG_6656 (900x1024)[1] IMG_6656 (900x1024)[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/IMG_6656-900x10241-1-150x150.jpg)

![Container[1] Container[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/Container1-150x150.jpg)

![oilwaste[1] oilwaste[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/oilwaste1-150x150.jpg)

![partnerproducts[1] partnerproducts[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/partnerproducts1-150x150.jpg)

![CV3[1] CV3[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/CV31-150x150.jpg)

![waterzuivering[1] waterzuivering[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/waterzuivering1-150x150.jpg)