Thermal oxidation, (after burning, with or without heat reclamation,) of process air and/or vapors.

工艺废气的热氧化反应(燃烧后,有或无热量回收)

The origin of this air can be numerous; from dryers, printing presses, paint ovens and a lot of other thermal or biologic processes.

可以处理多种来源的废气,如来源自干燥机,印刷打印机,涂料炉,以及其它的加热或生物 反应过程中排放的工艺废气。

Combustors

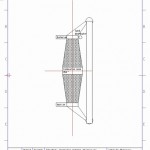

Combustors combine a combustion room with an internal (multi) fuel or pilot burner(s). These combustion rooms consist of a whole metallic triple wall, so no ceramics are used. Low maintenance costs are the result and short start-up and shutdown times are realizable.

Combustors have proved their liability hundreds of times and are very reliable. Typical temperatures in the flame can be set at a range from 600° C. up to 2000° C.

Such a design brings the advantage of a preheat section for the air to be processed. The air is preheated up to (400 – 600° C.) and that enhances the oxidation process considerably.

Quick and complete combustion even of cumbersome gas flows can be guarantied. This heat recovery, from the process itself, not only enhances the oxidation but is also the main reason for the low fuel consumption. In many cases, only the solvents in the air will be sufficient to supply for the caloric heat demand of the oxidation process.

Trickle flow reactors

滴流式反应器

When polluted process air is to be cleaned, one has several options: Scrubbing, (Bio) filtering, chemical treatment, and also Thermal Oxidation, burning the pollutants in the air flow.

处理被污染的工艺气体有很多种方法:水洗塔,(生物)过滤器,化学反应,以及热氧化,在空气流中燃烧污染物。

Due to the increasing energy consumption, the larger the amount of air to be treated the less attractive the last option is, unless of course one finds a simple way to recuperate the heat in the off gasses to reduce the costs for the fuel. This is done by (stainless) steel heat exchangers, by full bed ceramic pebbles heat recuperation and by floating pebble heat recuperation the so called Trickle flow reactor.

空气流量越大,能量消耗越多,这是最后一种方法的不足之处。如果能从尾气中回收热量,就可以节约燃料和费用,这可以通过(不锈)钢换热器,陶瓷蓄热床,或其它卵石类介质蓄 热来实现,也可以叫做滴流式反应器。

Sand or other intermediate is used to transport the heat from the outgoing gasses to the incoming air flow. A temperature difference between the inlet and the outlet can be as small as 50 degrees Celsius. All organic components are burned in the middle of the process where 850 degrees Celsius are maintained. Especially with large flows this is a very interesting technique.

砂子或其它介质只是用来把热量从出口气体传导到进口气体,这样进出口温度差在50 度左 右。所有的有机成分在设备中间,温度维持850 度左右的地方下燃烧,特别对大流量流体 这种技术非常重要。

![Container[1] Container[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/Container1-150x150.jpg)

![100_0063[1] 100_0063[1]](http://www.emgroup.nl/emg/wp-content/uploads/2017/03/100_00631-150x150.jpg)