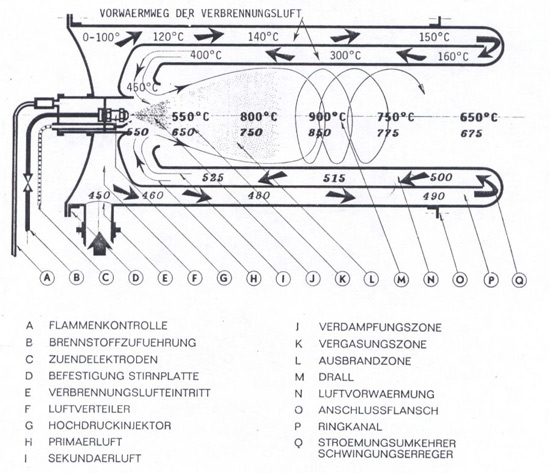

Combustors combine a combustion room with an internal (multy) fuel burner(s).

燃烧炉由一个燃烧室和一个(或多个)内置燃烧器组成。

Such a design brings the advantage of a preheat section for the combustion air by means of a triple combustor wall; this preheated air (400 – 600 degrees C) enhances the combustion process considerably.

燃烧炉的预热段由三层炉壁构成,这样设计的优势是通过预热空气到400~600C, 提 高了燃烧效率。

Quick and complete combustion, even of cumbersome fuels or gas flows, can be guarantied.

即使使用粘稠难燃的燃料或流动气体,也能保证快速并充分燃烧。

As a combustion room for Incinerators and R.T.O.’s the pre heating will bring high economy profits (e.g. 600 degrees C. heat recovery) and low maintenance cost due to the whole metallic design.

作为焚烧炉或RTO 的燃烧室,由于设备整体为金属结构设计,预热会带来很好的经 济效益(例如600C 的热量回收)并降低维修费用。

Short start-up and shutdown times are realizable, thus enabling the possibility to only start and operate the equipment when needed.

由于启动和停车时间很短,这样可以根据生产需要随时启动并操作设备。

Typical temperatures in the flame can be set at a range from 600 degrees C up to 2000 degrees C.

火焰温度可以设定在600 度到2000 度之间。

Combustors have proved their liability hundreds of times and are on behalf of the absence of any ceramic materials very reliable.

通过上百次的安全运行结果证明,金属制造的燃烧炉替代陶瓷材料产品是安全可靠 的。

Difficult fuels, e.g. G-faze, a rest glycerine product from the bio diesel production, are combusted completely before the exhaust gas enters into the boiler, preventing clogging and lowering efficiencies.

在尾气进入锅炉之前,有些难燃烧的燃料如G-faze, 从生物柴油中剩余的甘油产品,都可以被完全燃烧,这样避免了堵塞,降低效率。、